Update: November 14,2004 – I replaced the bilge pump in the master berth with a Rule 3700.

Three weekends ago I arrived late Friday evening to the sound of something running. It wasn’t but a moment before I realized the bilge pump (the ONLY bilge pump!) had been running dry for some unknown period of time due to the float switch failing. I am so lucky that nothing serious happened during the three weeks I was away from Tortuga. That weekend was spent cleaning up and re-wiring a new float switch and pump (Rule 1200) below the main berth flooring. I’ve always been concerned that Tortuga had only one bilge pump. The owners manual clearly shows this and the original wiring on the DC electrical panel only had provision (and space) for one. But I was lulled into false confidence since Tortuga’s wood hull was so tight, she never leaked!

This weekend the story changed dramatically! As usual, I performed a walk-around check of Tortuga upon arrival on Friday evening. To my disbelief, a sizeable amount of water was entering the bilge from the bow area about 4 planks up from the keel, approximately 6 feet aft of the bow. For those who have an Alaskan, it was directly below the the forward most removal floor panel in the V-berth. Upon closer inspection, there was an actual stream shooting out about 1 inch from near one of the seams. Fortunately, the new bilge pump had been doing a perfect job and only an inch or so of water was in the bilges. There is nothing like the fear of sinking to alter one’s priorities of work for the weekend. So instead of taking three days and painting, a second bilge pump installation was now at the top of the list.

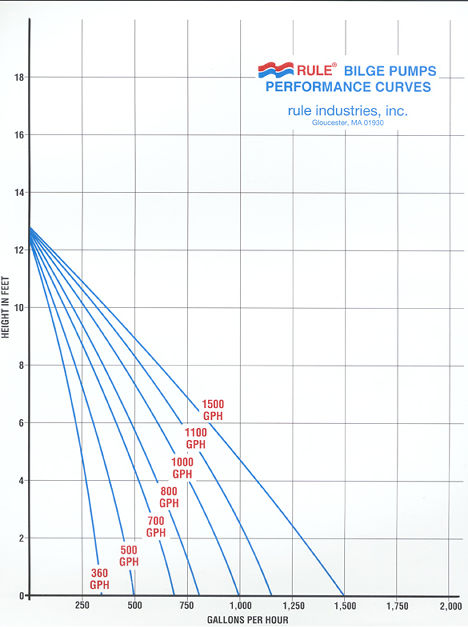

For those of you who are starting to get to know me: Yes – I’m anal about doing things right! So a simple bilge pump installation that could have been done in an afternoon, took two full days – doing it the “Jim” way. First, the electrical panel was only wired for a single pump. Worse yet, there was no indication at the helm if the pump was running, so when underway you would never have known if you where sinking until the water came over the floor boards. This meant I needed to redesign the electrical panel, run all new wiring to the V-berth (location for the second pump), and figure out where to run the pump discharge line overboard. First, I decided to eliminate the bilge pump switches from the electrical panel (it’s behind a solid wood door in the pilot house) and move them to the left of the wheel in clear visibility when operating the helm. I was able to stack two West Marine pump switch plates (with switch, status light, and fuse) above each other so that there was an obvious relationship to which panel belonged to which pump, forward (top) and aft pump (bottom). Moving the old pump wiring was straight forward. For the new forward pump, I ran 16-guage triplex wire down to the V-berth. This is where leaving a pull-string in the wiring channel between floors has proved itself valuable many times. The aft bilge pump is a Rule 1200 gallon per hour unit. I chose a Rule 2000 GPH unit for the forward pump, thinking that if it ever came on, I needed some real pumping power because something was drastically wrong! The pump location and float switch are approximately 3/4″ higher than the aft bilge pump. That allows the aft pump to be the primary one with the forward pump not activating until the aft one can’t keep up. In choosing pump capacity, please pay careful attention to the charts below. If you take the Rule 2000 as an example, I have a head height of 3 feet, that translates on the graph to about 1,700 GPH maximum capacity. You also need to take into account hose fittings, elbow, style of hose, etc. I would be willing to bet, that under ideal conditions, the configuration I installed could only handle about 1,500 gallons per hour. To scare each of you into reality, let’s calculate how much water can come into your boat. Let’s take a typical failure, a 1 1/2″ through-hull fitting breaks or the hose ruptures. So, the area of a 1.5 inch hose opening is 1.77 sq. inches (or 0.01 sq. ft.). If the hole is 4 feet below the water line, then 0.01 * 4 * 3,600 = 100 gallons per minute (or 5,990 gallons per hour!) Even with both of my pumps running at peak performance, I will sink! Please note, I do have a third manual pump. I can see Stephanie now – sitting at the stairs pumping that handle for all she’s worth

For those of you who are starting to get to know me: Yes – I’m anal about doing things right! So a simple bilge pump installation that could have been done in an afternoon, took two full days – doing it the “Jim” way. First, the electrical panel was only wired for a single pump. Worse yet, there was no indication at the helm if the pump was running, so when underway you would never have known if you where sinking until the water came over the floor boards. This meant I needed to redesign the electrical panel, run all new wiring to the V-berth (location for the second pump), and figure out where to run the pump discharge line overboard. First, I decided to eliminate the bilge pump switches from the electrical panel (it’s behind a solid wood door in the pilot house) and move them to the left of the wheel in clear visibility when operating the helm. I was able to stack two West Marine pump switch plates (with switch, status light, and fuse) above each other so that there was an obvious relationship to which panel belonged to which pump, forward (top) and aft pump (bottom). Moving the old pump wiring was straight forward. For the new forward pump, I ran 16-guage triplex wire down to the V-berth. This is where leaving a pull-string in the wiring channel between floors has proved itself valuable many times. The aft bilge pump is a Rule 1200 gallon per hour unit. I chose a Rule 2000 GPH unit for the forward pump, thinking that if it ever came on, I needed some real pumping power because something was drastically wrong! The pump location and float switch are approximately 3/4″ higher than the aft bilge pump. That allows the aft pump to be the primary one with the forward pump not activating until the aft one can’t keep up. In choosing pump capacity, please pay careful attention to the charts below. If you take the Rule 2000 as an example, I have a head height of 3 feet, that translates on the graph to about 1,700 GPH maximum capacity. You also need to take into account hose fittings, elbow, style of hose, etc. I would be willing to bet, that under ideal conditions, the configuration I installed could only handle about 1,500 gallons per hour. To scare each of you into reality, let’s calculate how much water can come into your boat. Let’s take a typical failure, a 1 1/2″ through-hull fitting breaks or the hose ruptures. So, the area of a 1.5 inch hose opening is 1.77 sq. inches (or 0.01 sq. ft.). If the hole is 4 feet below the water line, then 0.01 * 4 * 3,600 = 100 gallons per minute (or 5,990 gallons per hour!) Even with both of my pumps running at peak performance, I will sink! Please note, I do have a third manual pump. I can see Stephanie now – sitting at the stairs pumping that handle for all she’s worth

It only goes to say that most marine engineering books recommend 4 pumps for a vessel the size of Tortuga!

Flow rate of leak in boat:

Q = 3,600 (A) (H)Q = gallons per minute of water coming in

A = area of hole in square feet

H = height of water over hole in feet, to bottom of the openingRemembering that the area of a circle = d^2 * 0.7854

Patch or cover thickness to withstand water pressure (patch over hole):

T = square root of: 48 (H) (L2)1000

T = thickness of wood or plywood patch in inches

H = height of water above bottom of hole, in feet

L = length of patch, longest distance between supports, in feet

OK – we now have a thorough appreciation for why we have multiple bilge pumps. To complete the installation I needed to run the pump discharge overboard. I elected to use the 1 1/8″ white sanitation hose sold by West Marine. This is a smooth-wall hose and clamps easily compared with the spiral clear hose. One of my to-do-list items was to track down and redraw the though-hole diagram for Tortuga. To my surprise there was an un-used hole in the forward starboard side. It may have been part of an old shower sump system. When I took the old hose off, the plastic through-hull broke right at the ring base. I only tell this story, because you should have seen me floating around the boat in the toy raft I borrowed in order to replace the fittings on the outside near the water line. It was comic relief to say the least.

Well – the job was completed and hopefully the leak will not get worse until I can have Tortuga pulled out in June. A minor improvement in the terminal block for the wiring still needs to be completed to match the aft pump configuration. But that can wait until the next trip.

Forward and aft switches at the helm station on Tortuga

Here are some questions I have to anyone who has some advice. Why is it that Rule chose to use 1 1/8″ discharge tube size? There are no fittings sold by West Marine to handle 1 1/8″ hose (no elbows, no tees, etc.). Why is it that there are no bronze through-hull fittings in 1 1/8″ size? I hate plastic plumbing parts!

Ships’ Bilge Pumps: A History of Their Development, 1500–1900 by Thomas J. Oertling. All wooden ships leak, a stark fact that has terrified sailors since the earliest days of ocean travel. Maritime historical literature is filled with horrific descriptions of being aboard a slowly sinking ship. Starting from this human perspective, Thomas J. Oertling traces the five-hundred-year evolution of a seemingly mundane but obviously important piece of seafaring equipment in this one-of-a-kind history. Beginning with early-sixteenth-century documents that recorded bilge pump design and installation and ending late in the nineteenth century, when bilge pumps were being mass-produced, Oertling covers a period of radical technological change. He describes the process of making long wooden pump tubes by hand, as well as the assembly of the machine-crafted pumps that helped revolutionize ship construction and design. Also given in detail are the creation, function, and development of all three types of pumps used from about 1500 to well into the nineteenth century: the burr pump, the suction or common pump, and the chain pump. Of further interest is Oertling’s overall examination of the nature and management of leaks in ships’ hulls. Line drawings and photographs illustrate the text. 6×9. 128 pp. 39 halftones. 23 line drawings. Bib. Index. $17.95 paper

All wooden ships leak, a stark fact that has terrified sailors since the earliest days of ocean travel. Maritime historical literature is filled with horrific descriptions of being aboard a slowly sinking ship. Starting from this human perspective, Thomas J. Oertling traces the five-hundred-year evolution of a seemingly mundane but obviously important piece of seafaring equipment in this one-of-a-kind history. Beginning with early-sixteenth-century documents that recorded bilge pump design and installation and ending late in the nineteenth century, when bilge pumps were being mass-produced, Oertling covers a period of radical technological change. He describes the process of making long wooden pump tubes by hand, as well as the assembly of the machine-crafted pumps that helped revolutionize ship construction and design. Also given in detail are the creation, function, and development of all three types of pumps used from about 1500 to well into the nineteenth century: the burr pump, the suction or common pump, and the chain pump. Of further interest is Oertling’s overall examination of the nature and management of leaks in ships’ hulls. Line drawings and photographs illustrate the text. 6×9. 128 pp. 39 halftones. 23 line drawings. Bib. Index. $17.95 paper

[…] Bilge Pumps: Your first line of defense […]